Potato flakes are products obtained by dehydration and drying, resulting in flaky or fine powdery substances. They are collectively referred to as potato whole powder. During the production process, the integrity of potato cells is preserved, retaining the natural flavor of potatoes.

What are Potato Flakes?

Potato flakes are a type of cooked and dehydrated potato food and material for the uses of direct use, food production, and other products.

Many people call potato flakes potato powder, potato flour, or mashed potato powder, but they are actually different potato products.

Generally, there are three types of mashed potato powder: potato granules, potato flakes, and milled potato flakes (some also call it potato flour).

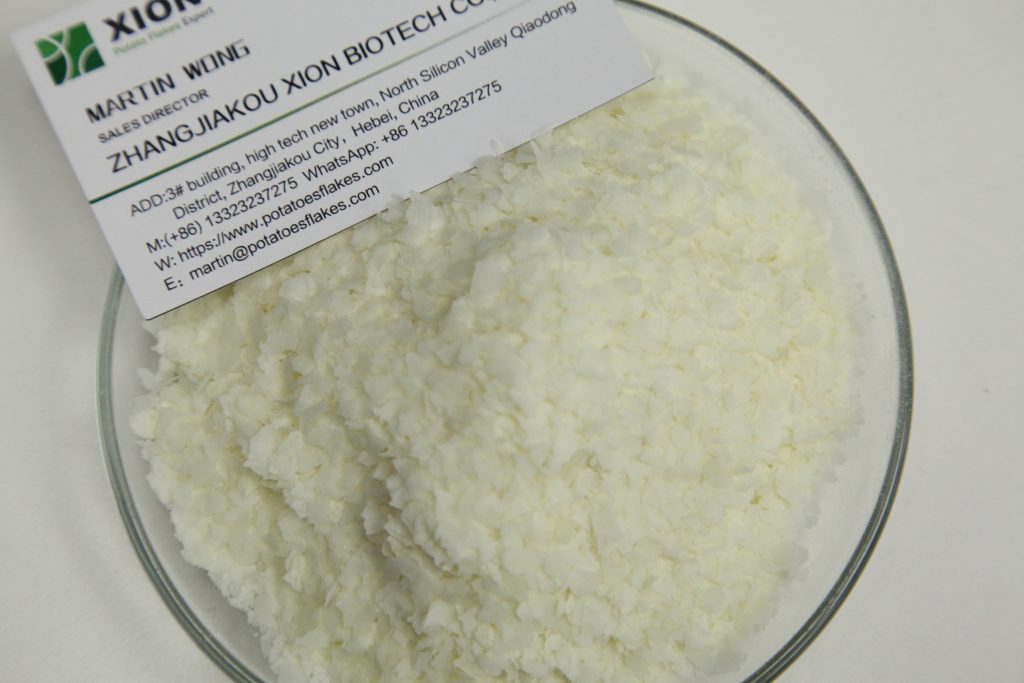

Potato flakes are easily distinguishable by sight. They appear as snowflake-like flakes, primarily in colors such as white, light yellow, and yellow. Some potato flakes also come in red and purple. Potato flakes are rarely seen in local supermarkets and markets because they are generally used as ingredients in snack foods, baked goods, and other products.

Below, we will provide a simple comparison of these three types of potato-based products.

Granules:

- Produced using hot air drying technology.

- Exists in the form of potato cell monomer granules or aggregates of several cells.

- Abbreviated as granule whole powder.

Flakes:

- Produced using drum drying technology.

- Irregular flakes range from 0.1 to 0.25 mm thick and 3 to 10 mm in diameter.

- We usually use a 20-mesh sieve, which gives an average diameter of 3 mm.

Flour:

- We can make fine potato powder by grinding dehydrated potato products

- Abbreviated as fine powder.

Production Yield: Among the three types of whole powder, potato flakes, and granules have the highest production yields in actual production. potato flakes are the main product in China currently. Many European and American manufacturers produce more potato granules than potato flakes.

How are Potato Flakes Made? The Details

The process of potato flakes production is a little complex including Selecting raw materials, washing, peeling, selecting, slicing, rinsing, pre-cooking, cooling, steaming, mashing, dehydration, and drying.

In the whole process, the most important steps are Raw Material Selection, Potato Peeling, Color Protection, and drying.

Raw Material Selection:

- Crucial Considerations: The choice of potato variety is crucial for processing potato flakes. Varieties should have high dry matter and low reducing sugar and harmful substance content, with minimal sprouting and a light color. They should also be free from significant diseases.

Potato Peeling:

- Importance: Regardless of the processing method used, potatoes need to be peeled to achieve high-quality potato flakes. Potato peels contain toxic compounds like solanine and nitrates. Peeling reduces the content of these compounds, ensuring the safety of the potato flakes.

- Common Methods:

- Traditional mechanical peeling methods result in significant potato loss, ranging from 15% to 50%.

- Steam peeling is the most efficient method, causing only 4% to 6% loss. It also has the highest efficiency, processing up to 3000 potatoes every 6 seconds.

Color Protection:

- Critical Aspect: Color protection is critical for the appearance and quality of potato flakes.

- Formation of Quinone Compounds: Processing steps like peeling and slicing can cause cell damage, leading to the formation of quinone compounds from polyphenol oxidase reacting with polyphenols. These quinone compounds can further react with amino acid groups in potato cells, resulting in browning.

- Effective Methods:

- The most effective method involves combining color protectants to control usage while ensuring effectiveness. For example, combining citric acid and D-sodium erythorbate enhances color protection. Combining vitamin C, phytic acid, citric acid, and L-cysteine effectively inhibits browning, achieving optimal color protection.

Drying the potato mash

- Hot air drying and vacuum freeze drying are the two main ways of drying the potato mash.

Drum Drying:

- Widely Used Method: Drum drying is the main method for drying potato flakes.

- Influence of Drying Temperature: The amount of reducing sugars in potato flakes made with hot air drying is strongly affected by the drying temperature. When the temperature goes up, the reducing sugar content first rises, then falls. Meanwhile, the vitamin C content goes down as the drying temperature increases.

- Drawbacks: While drum drying is simple and cost-effective, it damages the microstructure of potatoes, inhibiting moisture and oil penetration and reducing cohesion. It also results in decreased whiteness and various degrees of browning and oxidation in potato flakes.

How to make potato flakes at home?

Industrial-scale production requires specialized equipment and processes to ensure marketable quality. However, you can also make small quantities at home. But it is very difficult to make potato flakes by hand, the outcomes will be more like potato flour. You still can try this:

- Select fresh potatoes.

- Peel the potatoes.

- Steam or boil the potatoes until tender.

- Mash the cooked potatoes into a puree.

- Spread the potato puree thinly.

- Bake or microwave until dry.

- Collect and grind the dried potato puree to make potato flakes.

Note: The ratio of potatoes to potato flakes is typically 5:1, meaning 5 kilograms of potatoes yield approximately 1 kilogram of potato flakes.

Leave a Comment