เกล็ดมันฝรั่ง เป็นส่วนประกอบสำคัญในทันที มันฝรั่งบด, ของว่าง, และการผลิตอาหาร. มีประสิทธิภาพสูง สายการผลิตเกล็ดมันฝรั่ง ต้องการมากกว่าแค่วัตถุดิบ แต่ต้องการอุปกรณ์ที่ได้รับการออกแบบทางวิศวกรรมอย่างแม่นยำในทุกขั้นตอน.

คู่มือนี้แนะนำไฟล์ 17 เครื่องจักรที่จำเป็น ในสายการผลิตมันฝรั่งเกล็ดที่ทันสมัย. อุปกรณ์แต่ละชิ้นได้รับการออกแบบมาเพื่อประสิทธิภาพ, สุขอนามัย, และมีคุณภาพสม่ำเสมอ.

1. เครื่องซักผ้าแนวตั้ง – การทำความสะอาดและการทำลายอย่างมีประสิทธิภาพ

เครื่องซักผ้าแนวตั้งเป็นด่านแรกในการป้องกันสิ่งสกปรกและการปนเปื้อน.

ฟังก์ชั่นที่สำคัญ:

ห้องซักผ้า: ช่องทำความสะอาดที่มีการควบคุมช่วยให้มั่นใจว่าสามารถล้างมันฝรั่งสดได้ล้ำลึก.

การควบคุมการไหลของน้ำ: เครื่องบินไอพ่นที่แข็งแกร่งแต่นุ่มนวลช่วยขจัดดินและเศษซากโดยไม่ทำลายมันฝรั่ง.

การทำลายล้าง: โดยใช้แรงโน้มถ่วงและความหนาแน่นต่างกัน, หินจะถูกแยกออกจากกันอย่างมีประสิทธิภาพ.

ปล่อยอัตโนมัติ: มันฝรั่งที่สะอาดจะถูกย้ายไปยังขั้นตอนถัดไปโดยไม่มีการแทรกแซงด้วยตนเอง.

2. เครื่องซักผ้าแนวนอน – การทำความสะอาดขั้นที่สอง & การกำจัดสิ่งเจือปน

เครื่องสแตนเลสนี้เพิ่มประสิทธิภาพการทำความสะอาดด้วยกลไกแบบเกลียวและระบบน้ำหมุนเวียน.

ไฮไลท์:

บูรณาการการให้อาหาร, ทำความสะอาด, การกำจัดสิ่งเจือปน, และจำหน่าย.

ตัวกรองภายในแยกของเสียออกจากน้ำเพื่อกระบวนการที่ถูกสุขลักษณะ.

ลดความจำเป็นในการทำความสะอาดด้วยตนเองและปรับปรุงสุขอนามัยเกรดอาหาร.

3. เครื่องปอกเปลือกด้วยไอน้ำประสิทธิภาพสูง – การแยกผิวอย่างรวดเร็ว

ออกแบบมาเพื่อเครื่องแบบ, การบำบัดด้วยไอน้ำแรงดันสูง, เครื่องนี้จะคลายเปลือกมันฝรั่งเพื่อให้ดึงออกได้ง่าย.

คุณสมบัติ:

การออกแบบถังหมุน: ช่วยให้มั่นใจได้ถึงการสัมผัสไอน้ำ.

โหลด/ขนถ่ายอัตโนมัติ

การควบคุมห้องอบไอน้ำ: อุณหภูมิสม่ำเสมอเพื่อการปอกที่สมบูรณ์แบบโดยไม่ทำลายเยื่อกระดาษ.

4. สถานีปอกเปลือกมันฝรั่ง – การกำจัดผิวหนังโดยใช้แปรง

หลังจากไอน้ำคลายตัวแล้ว, มันฝรั่งจะถูกป้อนเข้าไปในสถานีนี้ โดยที่แปรงที่หมุนได้จะลอกเปลือกออก.

ประโยชน์:

การก่อสร้างสแตนเลส ช่วยให้มั่นใจได้ถึงความทนทานและสุขอนามัย.

ระบบระบายของเสีย ส่งสกินโดยตรงไปยังถังกำจัด.

ระบบสายพานลำเลียงแบบเฮลิคอล เพื่อการเคลื่อนย้ายวัสดุที่ราบรื่น.

5. แพลตฟอร์มการคัดแยก – การตรวจสอบด้วยตนเองเพื่อการควบคุมคุณภาพ

ก่อนทำการหั่น, คนงานที่มีทักษะตรวจสอบและคัดแยกมันฝรั่งบนโต๊ะสายพานลำเลียงด้วยตนเอง.

วัตถุประสงค์:

กำจัดเน่าเสีย, พิการ, หรือชิ้นใหญ่.

รับประกันคุณภาพวัตถุดิบที่สม่ำเสมอสำหรับการประมวลผลขั้นปลาย.

6. เครื่องสไลซ์ที่แม่นยำ – ชิ้นมันฝรั่งที่สม่ำเสมอเพื่อเกล็ดที่ดีกว่า

เครื่องสไลด์หั่นมันฝรั่งเป็นชิ้นบางๆ สม่ำเสมอ ซึ่งเป็นกุญแจสำคัญในการสร้างเนื้อสัมผัสและความแห้งสม่ำเสมอ.

คุณสมบัติ:

ปรับความหนาของใบมีดได้

อัตราการแตกหักต่ำ

ผลผลิตสูงและจำหน่ายอัตโนมัติ

7. เครื่องลวก-แป้ง & การกำจัดน้ำตาล, การควบคุมจุลินทรีย์

การลวกเป็นสิ่งสำคัญสำหรับการกำจัดแป้งและการยับยั้งการทำงานของเอนไซม์.

ข้อมูลจำเพาะที่สำคัญ:

ช่วงอุณหภูมิ: 80–90°ซ

อ่างน้ำอุ่นด้วยไอน้ำ ช่วยให้มั่นใจได้ถึงการลวกที่สม่ำเสมอ.

สายพานลำเลียงแบบเกลียว กวนและลำเลียงชิ้นเพื่อการประมวลผลที่เหมาะสมที่สุด.

8. เครื่องทำความเย็น – การควบคุมอุณหภูมิหลังการลวก

ชิ้นที่แช่เย็นจะคงสีและเนื้อสัมผัสไว้ก่อนปรุงอาหาร.

ส่วนประกอบของระบบ:

อ่างน้ำหมุนเวียน

ไม้พายเกลียวสำหรับการเคลื่อนไหว

การตรวจสอบอุณหภูมิของน้ำเพื่อควบคุมการเกิดออกซิเดชัน

9. เครื่องทำไอน้ำ - การทำให้อ่อนลงขั้นสุดท้ายสำหรับการบด

นึ่งชิ้นเนื้อให้สุกเพื่อนำไปบด.

ไฮไลท์:

วาล์วไอน้ำควบคุมด้วยเซอร์โว

สายพานลำเลียงแบบเกลียวคู่เพื่อการกระจายความร้อนที่สม่ำเสมอ

การควบคุมอุณหภูมิแบบเรียลไทม์, ความดัน, และอัตราการป้อน

10. เครื่องบดมันฝรั่ง - การบดที่ราบรื่นและสม่ำเสมอ

มันฝรั่งปรุงสุกจะถูกบดให้เป็นเนื้อเดียวกัน.

บูรณาการกับหม้อหุงไอน้ำ, เครื่องผลิตเยื่อกระดาษช่วยให้มั่นใจได้ว่ากระบวนการอบแห้งจะเป็นไปอย่างราบรื่น.

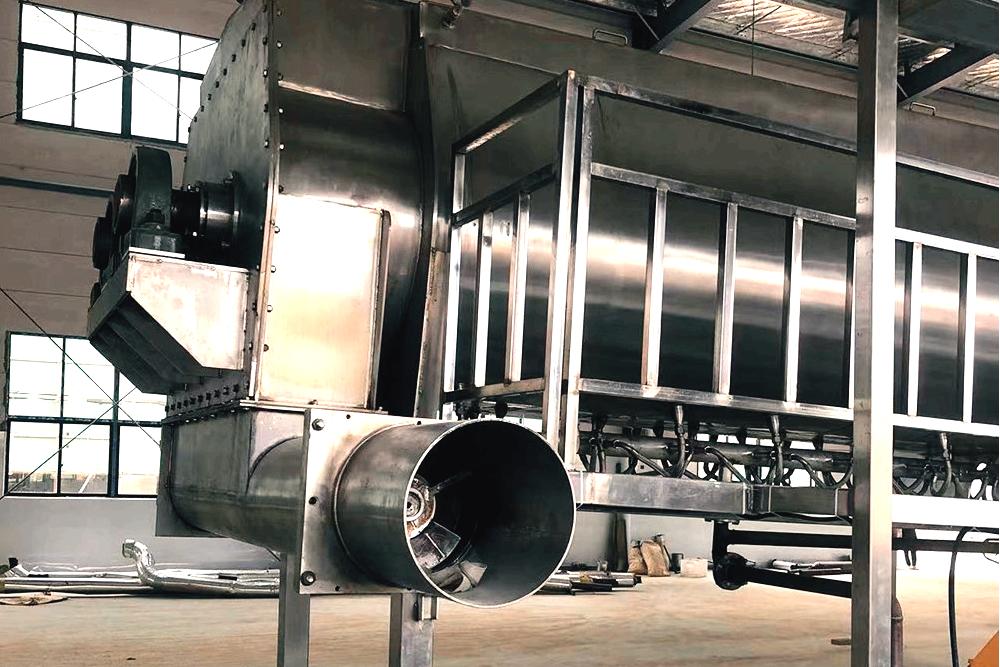

11. เครื่องอบผ้าแบบดรัม – เปลี่ยนมันฝรั่งบดให้เป็นเกล็ด

นี่คือแกนหลักของการผลิตมันฝรั่งเกล็ด.

ข้อกำหนด:

ดรัมหมุนความเร็วสูงพร้อมพื้นผิวที่ให้ความร้อน (150–170°ซ)

การอบแห้งแบบชั้นบางภายในไม่กี่วินาที

ใบมีดแบบนิวแมติกจะขูดสะเก็ดแห้งออก

ควบคุม PLC อย่างสมบูรณ์ด้วย HMI หน้าจอสัมผัส

12. เครื่องบดหลัก – ทำลายแผ่นแห้งเป็นชิ้นเกล็ด

เชื่อมต่อกับเครื่องอบผ้าแบบดรัม, มันบดแผ่นแห้งให้เป็นเกล็ดขนาดที่จัดการได้.

ตัวเบี่ยงลม ป้องกันไม่ให้วัสดุเปียกกลับเข้าสู่ระบบ.

13. สายพานลำเลียงแบบไซโคลน – การขนส่งด้วยลมที่มีประสิทธิภาพ

ใช้การไหลเวียนของอากาศแบบแรงเหวี่ยงเพื่อเคลื่อนย้ายสะเก็ดจากเครื่องบดไปยังระบบการสร้างรูปร่างหรือการทำให้เป็นเม็ด.

ข้อดี:

ไม่มีชิ้นส่วนที่เคลื่อนไหว → การบำรุงรักษาต่ำ

ระบบซีล → ไม่มีฝุ่น, สภาพแวดล้อมที่สะอาดยิ่งขึ้น

14. เครื่องกรองแบบสั่น – การแยกขนาดเกล็ดที่แม่นยำ

จัดเรียงเกล็ดตามรูปร่างและขนาดอนุภาค.

ส่วนประกอบ:

โครงสแตนเลส

เลเยอร์หน้าจอหลายชั้นเพื่อการให้คะแนนที่แม่นยำ

บูรณาการอย่างราบรื่นกับเครื่องป้อนสุญญากาศหรือไซโคลน

15. เครื่องบดมันฝรั่งเกล็ด – การบดผงขั้นสุดท้าย

แปลงเกล็ดให้เป็นเม็ดหรือผงที่ละเอียดยิ่งขึ้น.

คุณสมบัติที่สำคัญ:

ปรับความละเอียดในการบดได้

ระบบโรเตอร์ความเร็วสูง

รับประกันความสม่ำเสมอของผลิตภัณฑ์และความบริสุทธิ์

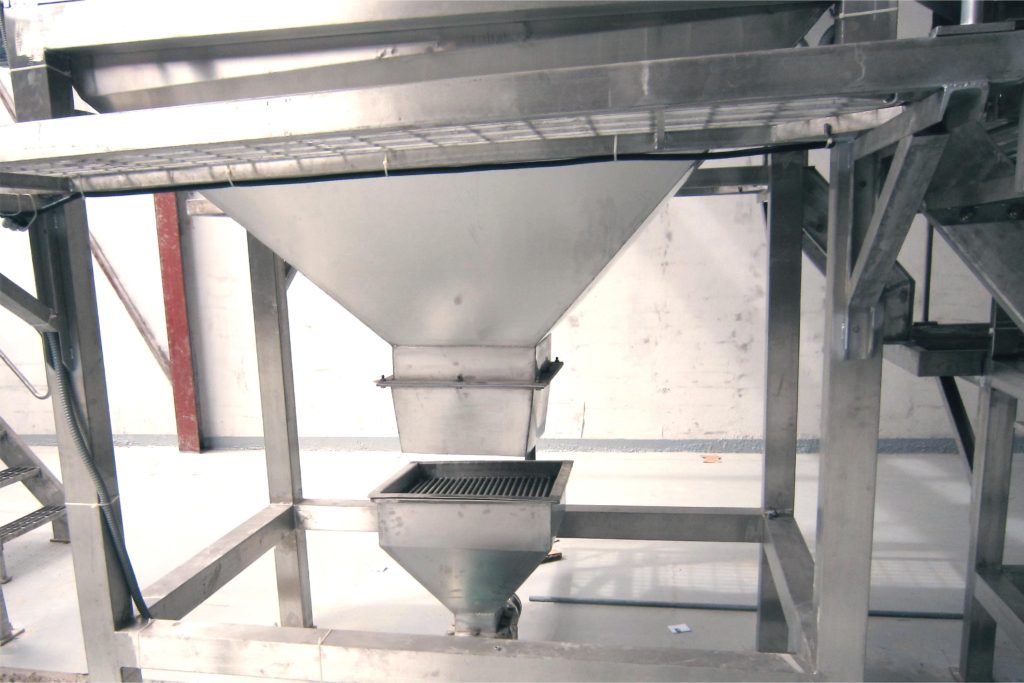

16. การชั่งน้ำหนัก & สถานีจ่ายสาร – การบรรจุและการควบคุมแบทช์ที่แม่นยำ

ตรวจสอบและควบคุมปริมาณของเกล็ดมันฝรั่งหรือผงขั้นสุดท้ายก่อนบรรจุภัณฑ์.

ประโยชน์:

ช่วยลดของเสียจากการเติมมากเกินไป

เพิ่มความพึงพอใจให้กับลูกค้า

เหมาะอย่างยิ่งสำหรับการใช้งานร่วมกับสายการบรรจุอัตโนมัติ

17. ระบบบรรจุภัณฑ์สูญญากาศหรือซีลความร้อน

จบกระบวนการด้วยบรรจุภัณฑ์เกรดอุตสาหกรรม.

ตัวเลือกได้แก่:

ถุง PE ปิดผนึกด้วยความร้อน

เย็บกระเป๋าด้านนอก (เช่น, ปอกระเจาหรือพลาสติกทอ)

ระบบสายพานลำเลียงเพื่อย้ายถุงปิดผนึกไปยังการจัดเก็บหรือโซนจัดวางบนพาเลท

ตัวอย่างพารามิเตอร์ทางเทคนิค

| พารามิเตอร์ | ช่วงค่า |

|---|---|

| ความชุ่มชื้นของเกล็ดสุดท้าย | 6–8% |

| ความหนาแน่นเป็นกลุ่ม | 250–350 กก./ลบ.ม |

| ขนาดเกล็ด | 1–3 มม |

| ความสามารถในการประมวลผล | 0.5–5 ตัน/ชั่วโมง |

| แรงดันไอน้ำสำหรับการปรุงอาหาร | 0.6–1.2 เมกะปาสคาล |

| อุณหภูมิพื้นผิวของเครื่องเป่าดรัม. | 150–170°ซ |

บทสรุป

แบบครบวงจร สายการผลิตเกล็ดมันฝรั่ง สร้างขึ้นบนสิ่งเหล่านี้ 17 เครื่องจักรหลักให้ประสิทธิภาพสูง, คุณภาพของผลิตภัณฑ์ที่เหนือกว่า, และประสิทธิภาพที่สม่ำเสมอ. ไม่ว่าคุณจะสร้างโรงงานใหม่หรืออัพเกรดโรงงานที่มีอยู่, การเลือกอุปกรณ์ที่เหมาะสมในแต่ละขั้นตอนมีความสำคัญต่อความสำเร็จของคุณในอุตสาหกรรมแปรรูปอาหารที่มีการแข่งขันสูง.

ต้องการการสนับสนุนจากผู้เชี่ยวชาญในการสร้างสายการผลิตมันฝรั่งเกล็ดของคุณ?

✅ ติดต่อเราเพื่อรับการออกแบบที่กำหนดเอง, ข้อมูลจำเพาะของเครื่อง, และการวางแผนการจัดวาง.

ทิ้งข้อความไว้