Fiocchi di patate sono un ingrediente chiave nell'istante purè di patate, spuntini, e produzione alimentare. Una prestazione elevata linea di produzione di fiocchi di patate richiede più di semplici materie prime: ha bisogno di attrezzature ingegnerizzate in ogni fase.

Questa guida introduce il 17 macchine essenziali In una moderna linea di lavorazione dei fiocchi di patate. Ogni equipaggiamento è progettato per l'efficienza, igiene, e qualità costante.

1. Lavatrice verticale - pulizia e destinaggio efficienti

La rondella verticale è la prima linea di difesa contro lo sporco e la contaminazione.

Funzioni chiave:

Lavare la camera: Una cavità di pulizia controllata garantisce un lavaggio profondo di patate fresche.

Controllo del flusso d'acqua: Getti forti ma delicati rimuovono il terreno e i detriti senza danneggiare le patate.

Destoning: Usando le differenze di gravità e densità, Le pietre sono separate in modo efficiente.

Scarico automatico: Le patate pulite vengono spostate al passaggio successivo senza intervento manuale.

2. Lavatrice orizzontale - pulizia secondaria & Rimozione dell'impurità

Questa macchina in acciaio inossidabile migliora la pulizia con meccanismi a spirale e un sistema di acqua di circolazione.

Punti salienti:

Integra l'alimentazione, pulizia, Rimozione dell'impurità, e scarico.

I filtri interni separano i rifiuti dall'acqua per un processo igienico.

Riduce le esigenze di pulizia manuale e migliora i servizi igienico-sanitari alimentari.

3. Macchina a vapore ad alta efficienza-Separazione rapida della pelle

Progettato per l'uniforme, Trattamento del vapore ad alta pressione, Questa macchina allenta le pelli di patate per una facile rimozione.

Caratteristiche:

Design del tamburo rotante: Garantisce anche l'esposizione al vapore.

Caricamento/scarico automatico

Controllo della camera a vapore: Temperatura costante per il peeling ideale senza danneggiare la polpa.

4. Stazione di peeling di patate-Rimozione della pelle a base di spazzole

Dopo l'allentamento del vapore, Le patate vengono alimentate in questa stazione dove le pennelli rotanti spogliano le pelli.

Benefici:

Costruzione in acciaio inossidabile garantisce durata e igiene.

Il sistema di scarico dei rifiuti Invia le pelli direttamente ai serbatoi di smaltimento.

Sistema di trasporto elicoidale Per un movimento del materiale liscio.

5. Piattaforma di smistamento: ispezione manuale per il controllo di qualità

Prima di tagliare, I lavoratori qualificati ispezionano manualmente e ordinano patate su un trasporto.

Scopo:

Rimuovere il marcio, deforme, o pezzi di grandi dimensioni.

Garantire una qualità costante di materie prime per l'elaborazione a valle.

6. Slicer di precisione - Fette di patate uniformi per migliori fiocchi

La sorgente taglia le patate in fette sottili coerenti: key alla consistenza e all'uniformità dell'essiccazione.

Caratteristiche:

Spessore della lama regolabile

Basso tasso di rottura

Uscita elevata e scarico automatico

7. MACCHINA BLANCHING - amido & Rimozione dello zucchero, Controllo microbico

Bianching è fondamentale per la rimozione dell'amido e l'inattivazione degli enzimi.

Specifiche chiave:

Intervallo di temperatura: 80–90 ° C.

Baglie d'acqua riscaldata a vapore Garantisce Bianching uniforme.

Trasportatore a spirale agita e trasmette fette per un'elaborazione ottimale.

8. Macchina di raffreddamento-Controllo della temperatura post-blasching

Fette raffreddate mantengono il colore e la consistenza prima della cottura.

Componenti di sistema:

Bagno d'acqua circolante

Paddle a spirale per il movimento

Monitoraggio della temperatura dell'acqua per il controllo dell'ossidazione

9. Macchina da cottura a vapore - Ammorbidimento finale per schiacciamento

Il vapore cucina accuratamente le fette per schiacciare.

Punti salienti:

Valvole a vapore controllate dal servo

Trasportatore a spirale a doppia vite per distribuzione uniforme

Controllo in tempo reale della temperatura, pressione, e velocità di alimentazione

10. Mashing Maching di patate - Mashing liscio e coerente

Le patate cotte vengono schiacciate in una pasta uniforme.

Integrato con una cucina a vapore, La macchina per polpa garantisce una consegna regolare al processo di asciugatura.

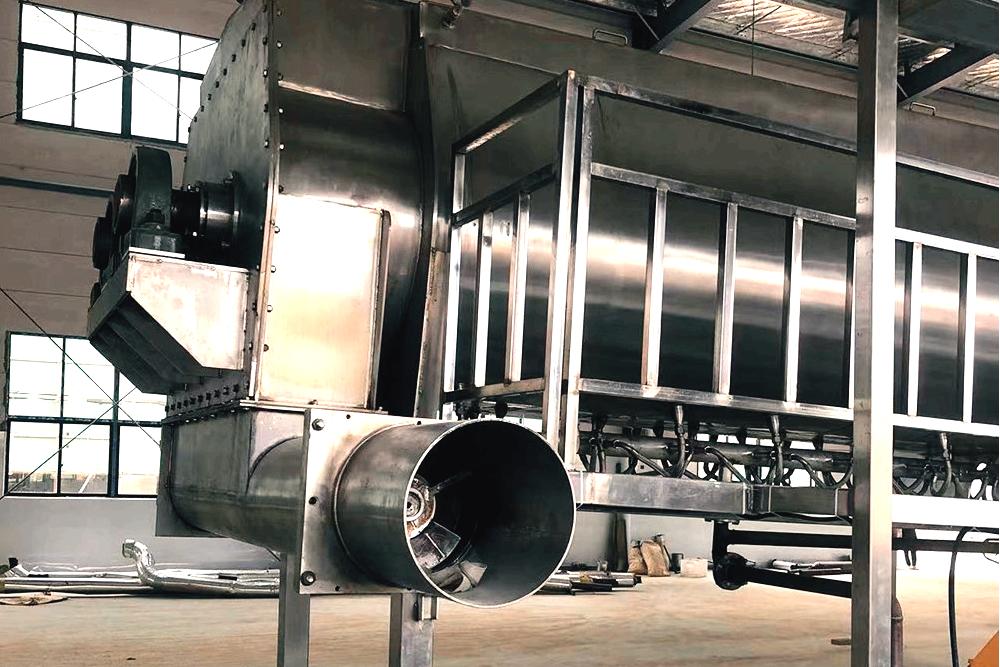

11. Asciugatrice di tamburi - trasformando la purè di patate in fiocchi

Questo è il nucleo della produzione di fiocchi di patate.

Specifiche:

Tamburo rotante ad alta velocità con superficie riscaldata (150–170 ° C.)

Asciugare a strato sottile in pochi secondi

La lama pneumatica raschia i scaglie essiccate

Completamente controllato con PLC con touchscreen HMI

12. Crusher primario: rompere i fogli secchi in pezzi di fiocchi

Collegato all'asciugatrice del tamburo, schiaccia i fogli secchi in dimensioni gestibili.

Deflettore pneumatico impedisce al materiale bagnato di rientrare nel sistema.

13. Ciclone trasportatore - trasporto pneumatico efficiente

Utilizza il flusso d'aria centrifugo per spostare i fiocchi dal frantoio al sistema di formazione o granulato.

Vantaggi:

Nessuna parte in movimento → bassa manutenzione

Sistema sigillato → nessuna polvere, ambiente più pulito

14. Setacciatore vibrato - Separazione accurata delle dimensioni del fiocco

Ordina i fiocchi in base alla forma e alla dimensione delle particelle.

Componenti:

Telaio in acciaio inossidabile

Più livelli di schermo per una classificazione precisa

Integrazione senza soluzione di continuità con sottovuoto o alimentazione ciclonale

15. Macinino a fiocchi di patate - macinatura in polvere finale

Converte i fiocchi in granuli più fini o polvere.

Caratteristiche principali:

Finezza regolabile

Sistema del rotore ad alta velocità

Garantisce l'uniformità del prodotto e la purezza

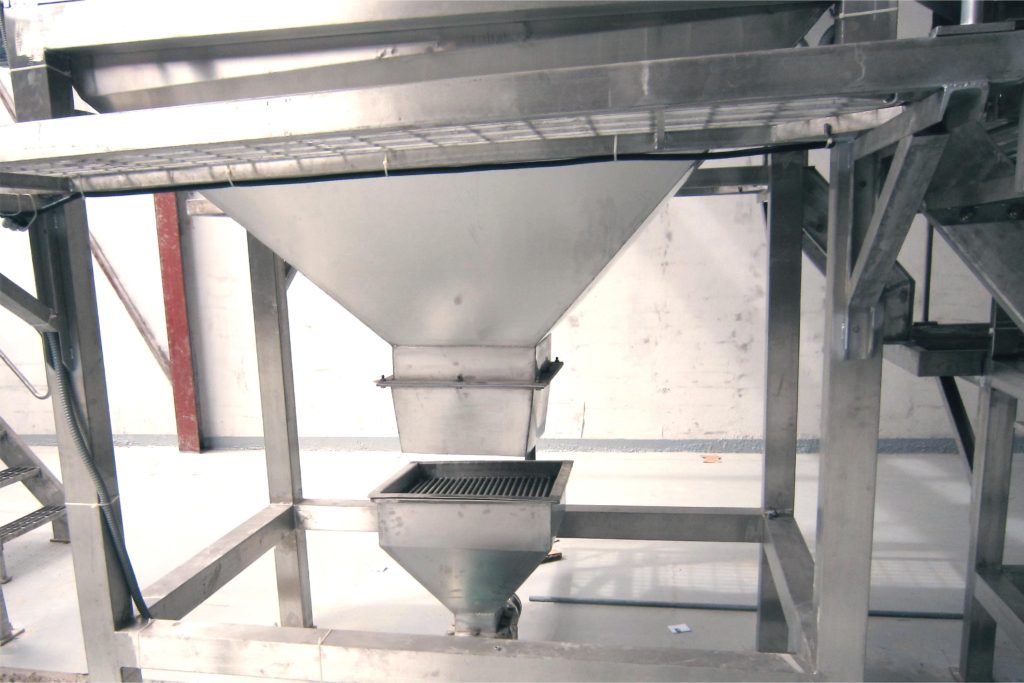

16. Pesatura & Stazione di dosaggio - Riempimento di precisione e controllo batch

Monitora e controlla la quantità di fiocchi di patate finali prima dell'imballaggio.

Benefici:

Riduce i rifiuti eccessiva

Aumenta la soddisfazione del cliente

Ideale per l'integrazione con linee di imballaggio automatizzate

17. Sistema di imballaggio a vuoto o calore

Termina il processo con l'imballaggio di livello industriale.

Le opzioni includono:

PE SEILAZIONE DI SOLO DI PE

Cuciture della borsa esterna (PER ESEMPIO., in plastica iuta o tessuta)

Sistema trasportatore per spostare i sacchetti sigillati in stoccaggio o la zona pallettizzazione

Parametri tecnici di esempio

| Parametro | Intervallo di valori |

|---|---|

| Umidità finale del fiocco | 6–8% |

| Densità di massa | 250–350 kg/m³ |

| Dimensione del fiocco | 1–3 mm |

| Capacità di elaborazione | 0.5–5 tonnellate/ora |

| Pressione del vapore per cucinare | 0.6–1.2 MPA |

| Temperatura superficiale asciugatrice. | 150–170 ° C. |

Conclusione

Un completamente integrato linea di produzione di fiocchi di patate costruito su questi 17 Le macchine core offrono un'efficienza elevata, qualità del prodotto superiore, e prestazioni coerenti. Sia che tu stia costruendo un nuovo impianto o aggiornando uno esistente, Selezionare l'attrezzatura giusta in ogni fase è fondamentale per il tuo successo nel settore della trasformazione alimentare competitiva.

Desideri supporto esperto nella costruzione della tua linea di patate?

✅ Contattaci per il design personalizzato, Specifiche della macchina, e pianificazione del layout.

Lascia un commento