Su Sızıntısına Etkisi, Yapı, ve Lezzet

Soyut

Yemek servisi ve merkezi mutfak müşterilerinden gelen sık sorulan sorulara yanıt olarak—"Olabilmek patates püresi yapılmış Patates gevreği ve sıcak suyun dondurulması, ve su çözüldükten sonra ayrılacak mı?”— karşılaştırmalı bir deney yapıldı, Gıda dondurma teknolojisine ilişkin literatür analiziyle desteklenmektedir. Bulgular: –20 °C'de depolama (geleneksel dondurma) Çözünme sonrasında gözle görülür su ayrımına yol açar, –40 °C'de hızlı donma sırasında (hızlı dondurma) bu tür sızıntıyı önler. Anahtar şunda yatıyor: donma oranı, hangisi belirler buz kristali boyutu ve dağılımı Ve, sonuç olarak, patates hücresi ve nişasta jeli yapısına verilen hasarın derecesi. Çalışma aynı zamanda dondurma ve hızlı dondurma arasındaki endüstriyel süreç farklılıklarını da değerlendiriyor, onların uygulamaları, ve maliyet etkileri, ve potansiyel hakkında bilgi sağlar lezzet etkileri.

1. Deneysel Tasarım ve Gözlemler

1.1 Numune Hazırlama

Ticari patates pulları sıcak su ile belirli bir sıcaklıkta yeniden sulandırıldı. 5:1 sudan pullara (w/w) oranında ve hafifçe karıştırılarak patates püresi elde edilir (standart catering mutfak hazırlığını taklit etmek).

1.2 –20 °C'de donma

Patates püresi tamamen donuncaya kadar -20°C'lik dondurucuya yerleştirildi., daha sonra soğutulmuş koşullar altında çözüldü. Gözlem: temiz su ayırma, yumuşatılmış doku, ve daha ince bir ağız hissi.

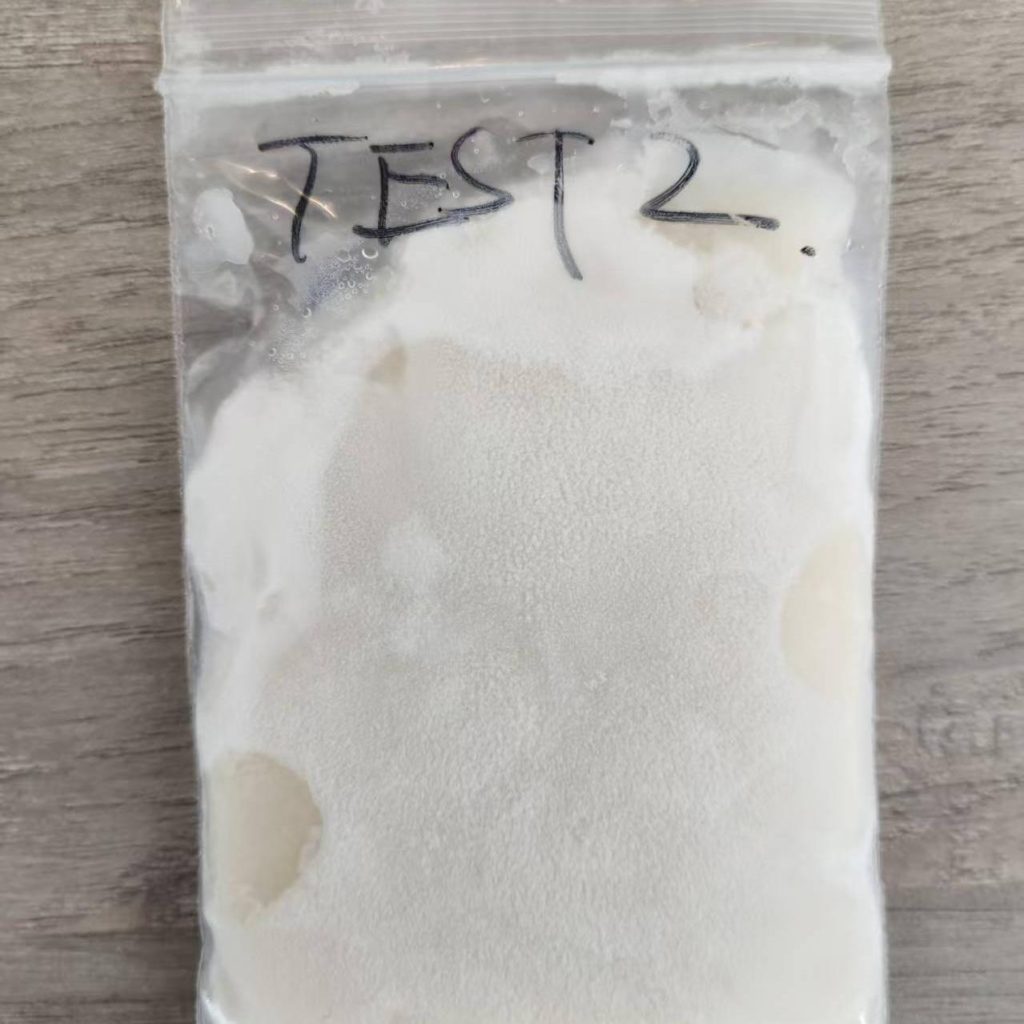

1.3 –40 °C'de Hızlı Dondurma

Aynı patates püresi partisi -40 °C'de hızla dondurulmuştur. (Patlama/spiral tünel veya kriyojenik sıvı nitrojen/CO₂ dondurmanın simülasyonu). Çözüldükten sonra, görünür su ayrımı yok gözlemlendi; yapısı ve ağız hissi iyi korunmuştur.

Özet:

Yavaş dondurma (–20 °C) → daha az çekirdeklenme bölgesi → daha büyük hücre dışı buz kristalleri → daha fazla yapısal hasar → daha fazla damlama kaybı.

Hızlı dondurma (–40 °C) → birçok çekirdeklenme bölgesi → daha küçük, eşit olarak dağılmış buz kristalleri → minimum hasar → damlama kaybı azaldı veya hiç yok.

2. Mekanistik Açıklama (Patates Gevreği Bazlı Patates Püresi Sistemleri)

2.1 Sulandırılmış Patates Püresinin Mikroyapısı

Sıcak su ile yeniden nemlendirilen patates pulları kompozit bir sistem oluşturur. parankima hücre parçaları bir içine gömülü jelatinleştirilmiş nişasta sürekli fazı. Donma-çözülme döngüleri bu matrisi bozar, Hücre duvarlarını parçalamak ve nişasta jeli ağlarını zayıflatmak, su tutma kapasitesinin azaltılması.

2.2 Donma Hızı ve Buz Kristali Morfolojisi

Yavaş dondurma (–20 °C): Büyük hücre dışı buz kristalleri hücreleri ve jel ağlarını fiziksel olarak parçalıyor, Ozmotik gradyanları artırın, ve su göçünü teşvik etmek.

Hızlı dondurma (≤ –35 ila –40 °C): küçük, Hücrelerin hem içinde hem de dışında eşit şekilde dağılmış buz kristalleri oluşur, Mekanik hasarın ve ozmotik dengesizliğin en aza indirilmesi.

2.3 Nişasta Retrogradasyonu ve Sinerezi

Çözüldükten sonra, jelatinleştirilmiş patates nişastası geçebilir gerileme, amiloz ve amilopektin zincirlerinin yeniden hizalandığı yer, jelin büzülmesine neden olur ve sinerez (su tahliyesi). Yavaş dondurma, daha büyük faz ayrımı yoluyla bunu hızlandırır; hızlı dondurma bunu yavaşlatır veya en aza indirir. Formülasyon ayarlamaları (örneğin, tuzlar, diş etleri, proteinler) donma-çözülme stabilitesini daha da geliştirebilir.

3. Endüstriyel Süreçler: Donma vs. Hızlı Dondurma

3.1 İşlem & Teçhizat

Geleneksel Dondurma (–18 ila –20 °C): Statik veya düşük hava akışlı soğuk hava deposu; basit ekipman; uzun donma süresi, kaba buz kristalleri.

Hızlı Dondurma (IQF):

Mekanik (hava püskürtme tünelleri/spiral dondurucular, plaka temaslı dondurucular) — yüksek verim, yüksek ısı transfer verimliliği.

Kriyojenik (sıvı nitrojen LN₂ veya CO₂) — ultra düşük sıcaklıklar, çok hızlı donma, kompakt ayak izi, yüksek değerli veya değişken talepli ürünler için idealdir.

3.2 Uygulamalar & Kalite

Hızlı dondurma, yiyeceklerin buzdolabında geçirdiği süreyi kısaltır. maksimum buz kristali oluşum bölgesi, damlama kaybını ve doku bozulmasını azaltmak — için çok önemlidir macunlar/püreler patates püresi gibi.

3.3 Maliyet Konuları

CAPEX: Mekanik hızlı dondurma hatları = daha yüksek ilk yatırım; kriyojenik sistemler = daha düşük başlangıç maliyeti.

OPEX:

Mekanik → elektrik ağırlıklı.

Kriyojenik → gaz tüketimi baskın (LN₂ ~0,4–1,6 kg/kg yiyecek).

4. Dondurmanın Potansiyel Lezzet Etkileri. Hızlı Dondurma

4.1 Yavaş Dondurma (–20 °C)

Nem geçişi yavaş dondurma ve çözme sırasında bazı çözünen maddeler eşit olmayan şekilde konsantre olabilir, algılanan tuzluluğu veya tatlılığı değiştirmek.

Daha büyük buz kristalleri hücreleri parçalıyor, ince tat değişikliklerini katalize edebilen hücre içi enzimleri serbest bırakır (lipitlerin oksidasyonu, enzimatik esmerleşme öncüleri).

Potansiyeli not dışı (örneğin, bayat, karton benzeri) Dondurulmuş depolama sırasında oksijene maruz kalma meydana gelirse oksidatif değişiklikler nedeniyle.

4.2 Hızlı Dondurma (–40 °C)

Hızlı immobilizasyon Suyun azalması ve yapısal hasarın azalması, enzimatik ve oksidatif reaksiyonları sınırlar, orijinal lezzet profilinin korunmasına yardımcı olmak.

Daha küçük buz kristalleri uçucu aromatik bileşikleri daha iyi korur, “taze pişmiş” patates aromasını korumak.

Azaltılmış faz ayrımı tuzun korunmasına yardımcı olur, yağ, ve tatlandırıcı maddeler çözüldükten sonra eşit şekilde dağıtılır.

Pratik paket servisi: Lezzetin korunması açısından, hızlı dondurma sadece dokuyu korumakla ve damlama kaybını önlemekle kalmaz, aynı zamanda tazeliği daha iyi korur, tereyağlı, Taze hazırlanmış patates püresine özgü hafif tatlı notalar.

5. Patates Gevreği Bazlı Patates Püresi Üretimi İçin Öneriler

Sipariş üzerine üretildi Yemek servisi için idealdir — donmaya bağlı retrogradasyonu ve sinerezi önler.

Dondurulması gerekiyorsa:

Hızlı dondurmayı kullanın (–40 °C veya daha düşük).

Daha hızlı dondurmak için ince tabaka yayma veya küçük birim paketleme uygulayın.

Donma-çözülme stabilitesini iyileştirmek için formülasyonda ince ayarlamalar yapmayı düşünün.

Yeniden kristalleşmeyi önlemek için kontrollü düşük sıcaklıklarda çözün.

Endüstriyel genişleme için:

Ekle paralel hızlı dondurma hattı Pulların yanında kullanıma hazır dondurulmuş patates püresi üretmek için kurutmadan önce.

Alternatif olarak, özel pazarlar için dondurarak kurutmayı keşfedin (farklı doku ve maliyet profili).

6. Çözüm

Deney: –20 °C donma → sudan ayırma; –40 °C hızlı dondurma → gözle görülür bir ayrım yok.

Mekanizma: Donma hızı buz kristalinin boyutunu belirler; Yavaş dondurma yapıya zarar verir ve nişastanın retrogradasyonunu hızlandırır; hızlı dondurma her ikisini de en aza indirir.

Lezzet: Hızlı dondurma, orijinal lezzet profilini yavaş dondurmaya göre daha iyi korur.

Endüstriyel uygulama: Hızlı dondurma, birinci sınıf kalite ve minimum duyusal bozulmaya yönelik dondurulmuş patates püresi ürünleri için tercih edilen yöntemdir..

Referanslar (NE)

Álvarez, M. D., & kanet, K. (1999). Kurutulmuş pullardan yapılan patates püresinin reolojik özellikleri: Malzemelerin etkisi ve donma. Avrupa Gıda Araştırması ve Teknolojisi, 209, 335–342. https://doi.org/10.1007/s002170050505

Jobling, S., Westcott, R. J., Fayans, A., Jeffcoat, R., & fışkırmak, G. (2002). Üç nişasta sentaz geninin antisens inhibisyonu ile donma-çözülmeye dayanıklı patates nişastası üretimi. Doğa Biyoteknolojisi, 20(3), 295–299. https://doi.org/10.1038/nbt0302-295

LibreText'ler. (bilinmiyor). Gıda dondurma. Alındı 2025, Kaliforniya Üniversitesi LibreTexts web sitesinden.

Güneş, D.-W., ve diğerleri. (2023). Gıdalarda buz morfolojisinin gözlemlenmesi ve ölçülmesi: Bir inceleme. Gıdalar, 12(21), 3987. https://doi.org/10.3390/foods12213987

Vang, W., Zhou, H., Hangi, H., & Hangi, M. (2016). Tuzların donma-çözülme stabilitesi üzerindeki etkileri, patates nişastasının jel mukavemeti ve reolojik özellikleri. Gıda Bilimi ve Teknolojisi Dergisi, 53(9), 3624–3631. https://doi.org/10.1007/s13197-016-2348-7

Yu, Y., Weng, W., Ren, Z., Zhang, Y., Li, P., & Şi, L. (2024). Donma-çözülme döngüsü sırasında patates püresinin kalitesinin bozulması: Nem ve mikro yapı açısından. Gıda Kimyası: X, 22, 101753. https://doi.org/10.1016/j.fochx.2023.101753

Çengel, e. A., & Ghajar, A. J. (2020). Isı ve Kütle Transferi: Temeller & Uygulamalar.

Hava Ürünleri. (2014). Üretim hattınız için doğru dondurma teknolojisini seçme.

James, S. J., & diğerleri. (2006). Kriyojenik gazlar ve sıvılarla soğutma ve dondurma: Statik ve sürekli ekipmanlar. Dondurulmuş Gıda İşleme ve Paketleme El Kitabı.

Yorum bırakın