Kesan ke atas pemisahan air, Struktur, and Flavor

Abstract

In response to frequent questions from foodservice and central kitchen customers—“Can kentang lenyek made from kepingan kentang and hot water be frozen, dan akan air terpisah apabila dicairkan?”—a comparative experiment was conducted, disokong oleh analisis sastera teknologi pembekuan makanan. Penemuan: Penyimpanan pada -20 ° C (Pembekuan konvensional) leads to visible water separation upon thawing, while –40 °C quick freezing (rapid freezing) prevents such exudation. The key lies in the freezing rate, which determines ice crystal size and distribution dan, consequently, the degree of damage to the potato cell and starch gel structure. The study also evaluates industrial process differences between freezing and quick freezing, their applications, and cost implications, and provides insight into potential flavor impacts.

1. Experimental Design and Observations

1.1 Sample Preparation

Commercial potato flakes were rehydrated with hot water at a 5:1 water-to-flakes (w/w) ratio and lightly stirred to form mashed potatoes (mimicking standard catering kitchen preparation).

1.2 Freezing at –20 °C

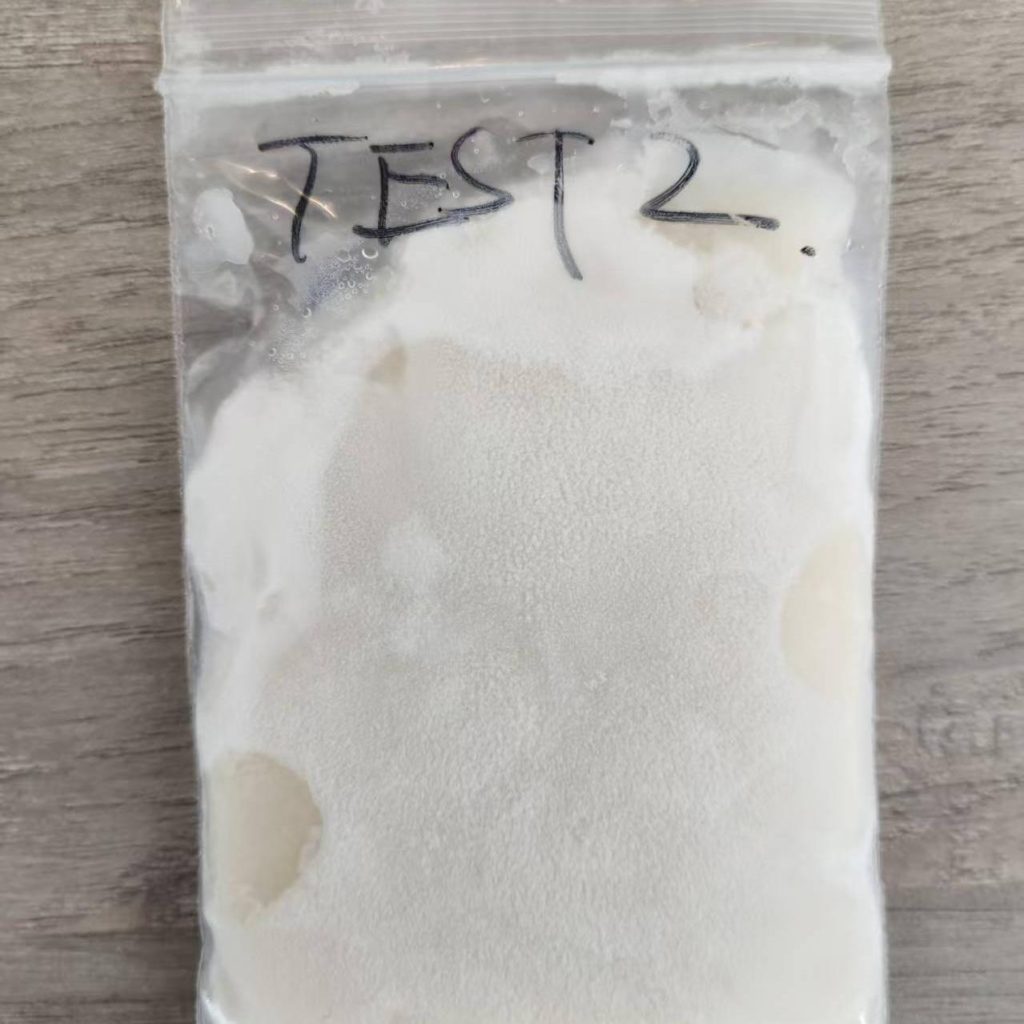

Mashed potatoes were placed in a –20 °C storage freezer until fully frozen, then thawed under refrigerated conditions. Observation: clear water separation, softened texture, and a thinner mouthfeel.

1.3 Quick Freezing at –40 °C

The same mashed potato batch was quick-frozen at –40 °C (simulating blast/spiral tunnel or cryogenic liquid nitrogen/CO₂ freezing). Upon thawing, no visible water separation was observed; structure and mouthfeel were well preserved.

Ringkasan:

-

Slow freezing (-20 ° C.) → fewer nucleation sites → larger extracellular ice crystals → more structural damage → greater drip loss.

-

Quick freezing (-40 ° C.) → many nucleation sites → smaller, evenly distributed ice crystals → minimal damage → reduced or no drip loss.

2. Mechanistic Explanation (Potato Flakes-Based Mashed Potato Systems)

2.1 Microstructure of Rehydrated Mashed Potatoes

Potato flakes rehydrated with hot water form a composite system of parenchyma cell fragments embedded in a gelatinized starch continuous phase. Freeze–thaw cycles disrupt this matrix, breaking down cell walls and weakening starch gel networks, reducing water-holding capacity.

2.2 Freezing Rate and Ice Crystal Morphology

-

Slow freezing (-20 ° C.): large extracellular ice crystals physically rupture cells and gel networks, increase osmotic gradients, and promote water migration.

-

Quick freezing (≤ –35 to –40 °C): small, evenly distributed ice crystals form both inside and outside cells, minimizing mechanical damage and osmotic imbalance.

2.3 Starch Retrogradation and Syneresis

Upon thawing, gelatinized potato starch may undergo retrogradation, where amylose and amylopectin chains realign, causing gel contraction and syneresis (water expulsion). Slow freezing accelerates this via greater phase separation; quick freezing slows or minimizes it. Formulation adjustments (cth., salts, gums, proteins) can further improve freeze–thaw stability.

3. Industrial Processes: Freezing vs. Pembekuan cepat

3.1 Process & Peralatan

-

Conventional Freezing (–18 to –20 °C): Static or low-airflow cold storage; simple equipment; long freezing time, coarse ice crystals.

-

Pembekuan cepat (IQF):

-

Mechanical (air blast tunnels/spiral freezers, plate contact freezers) — high throughput, high heat-transfer efficiency.

-

Cryogenic (liquid nitrogen LN₂ or CO₂) — ultra-low temperatures, very fast freezing, compact footprint, ideal for high-value or variable-demand products.

-

3.2 Aplikasi & Quality

Quick freezing shortens the time food spends in the maximum ice crystal formation zone, reducing drip loss and texture degradation — crucial for pastes/purees like mashed potatoes.

3.3 Cost Considerations

-

CAPEX: Mechanical quick-freeze lines = higher initial investment; cryogenic systems = lower initial cost.

-

OPEX:

-

Mechanical → electricity dominant.

-

Cryogenic → gas consumption dominant (LN₂ ~0.4–1.6 kg/kg food).

-

4. Potential Flavor Impacts of Freezing vs. Pembekuan cepat

4.1 Slow Freezing (-20 ° C.)

-

Moisture migration during slow freezing and thawing can concentrate certain solutes unevenly, altering perceived saltiness or sweetness.

-

Larger ice crystals rupture cells, releasing intracellular enzymes that may catalyze subtle flavor changes (oxidation of lipids, enzymatic browning precursors).

-

Potential for off-notes (cth., stale, cardboard-like) due to oxidative changes if oxygen exposure occurs during frozen storage.

4.2 Pembekuan cepat (-40 ° C.)

-

Rapid immobilization of water and reduced structural damage limit enzymatic and oxidative reactions, helping preserve the original flavor profile.

-

Smaller ice crystals retain volatile aromatic compounds better, maintaining the “fresh-cooked” potato aroma.

-

Reduced phase separation helps keep salt, fat, and flavoring agents evenly distributed after thawing.

Practical takeaway: From a flavor preservation standpoint, quick freezing not only maintains texture and prevents drip loss but also better retains the fresh, buttery, slightly sweet notes characteristic of freshly prepared mashed potatoes.

5. Recommendations for Potato Flakes-Based Mashed Potato Production

-

Made-to-order is ideal for foodservice — avoids freezing-induced retrogradation and syneresis.

-

If freezing is required:

-

Use quick freezing (–40 °C or lower).

-

Apply thin-layer spreading or small-unit packaging for faster freezing.

-

Consider formulation tweaks to improve freeze–thaw stability.

-

Thaw under controlled low temperatures to avoid recrystallization.

-

-

For industrial expansion:

-

Add a parallel quick-freeze line before drying to produce ready-to-use frozen mashed potatoes alongside flakes.

-

Sebagai alternatif, explore freeze-drying for specialty markets (different texture and cost profile).

-

6. Kesimpulan

-

Experiment: –20 °C freezing → water separation; –40 °C quick freezing → no visible separation.

-

Mechanism: Freezing rate determines ice crystal size; slow freezing damages structure and accelerates starch retrogradation; quick freezing minimizes both.

-

Flavor: Quick freezing retains original flavor profile better than slow freezing.

-

Industrial implication: Quick freezing is the method of choice for frozen mashed potato products intended for premium quality and minimal sensory degradation.

References (APA)

-

Alvarez, M. D., & Canet, W. (1999). Rheological properties of mashed potatoes made from dehydrated flakes: Effect of ingredients and freezing. European Food Research and Technology, 209, 335–342. https://doi.org/10.1007/s002170050505

-

Jobling, S., Westcott, R. J., Tayal, A., Jeffcoat, R., & Schwall, G. (2002). Production of a freeze–thaw-stable potato starch by antisense inhibition of three starch synthase genes. Nature Biotechnology, 20(3), 295–299. https://doi.org/10.1038/nbt0302-295

-

LibreTexts. (n.d.). Food freezing. Retrieved 2025, from University of California LibreTexts website.

-

Sun, D.-W., et al. (2023). Observation and measurement of ice morphology in foods: A review. Foods, 12(21), 3987. https://doi.org/10.3390/foods12213987

-

Wang, W., Zhou, H., Yang, H., & Cui, M. (2016). Effects of salts on the freeze–thaw stability, gel strength and rheological properties of potato starch. Journal of Food Science and Technology, 53(9), 3624–3631. https://doi.org/10.1007/s13197-016-2348-7

-

Yu, Y., Weng, W., Ren, Z., Zhang, Y., Li, P., & Shi, L. (2024). Quality deterioration of mashed potatoes during the freeze–thaw cycle: From the perspective of moisture and microstructure. Food Chemistry: X, 22, 101753. https://doi.org/10.1016/j.fochx.2023.101753

-

Çengel, Y. A., & Ghajar, A. J. (2020). Heat and Mass Transfer: Fundamentals & Aplikasi.

-

Air Products. (2014). Choosing the right freezing technology for your production line.

-

James, S. J., & others. (2006). Chilling and freezing by cryogenic gases and liquids: Static and continuous equipment. Handbook of Frozen Food Processing and Packaging.